Two thoughts on clamping:

- ?Conventional band clamp going all the way around:

I have a both.? The latter ones aren't cheap, but they work great

when you need to apply something in place.

On 7/15/2024 1:53 PM, David

Luckensmeyer via groups.io wrote:

Hi Brian:

?

Apologies, I

should have provided more detailed photos.

?

The bookcase

uprights in Zebrano are composed of a solid wood core

lamination with 3mm thick shop sawn Zebrano veneers on both

faces. This is the material I¡¯ve been machining for the half

laps.

?

?

?

If you look

closely at the photo below, you can see that I have edge

laminated the back side of the uprights with Zebrano

veneers, prior to the half lap machining process. This

worked well.

?

?

The problem

with the front edge is that it will be curved. I could not

machine the curve until the half lap joints were done. This

means that the front edge laminations have to be applied

after the machining is done.

?

The

horizontal shelves sit out from the uprights by 20mm. In the

photo below you can see how the shelves are proud, and you

can see the laminated nature of the uprights.

?

?

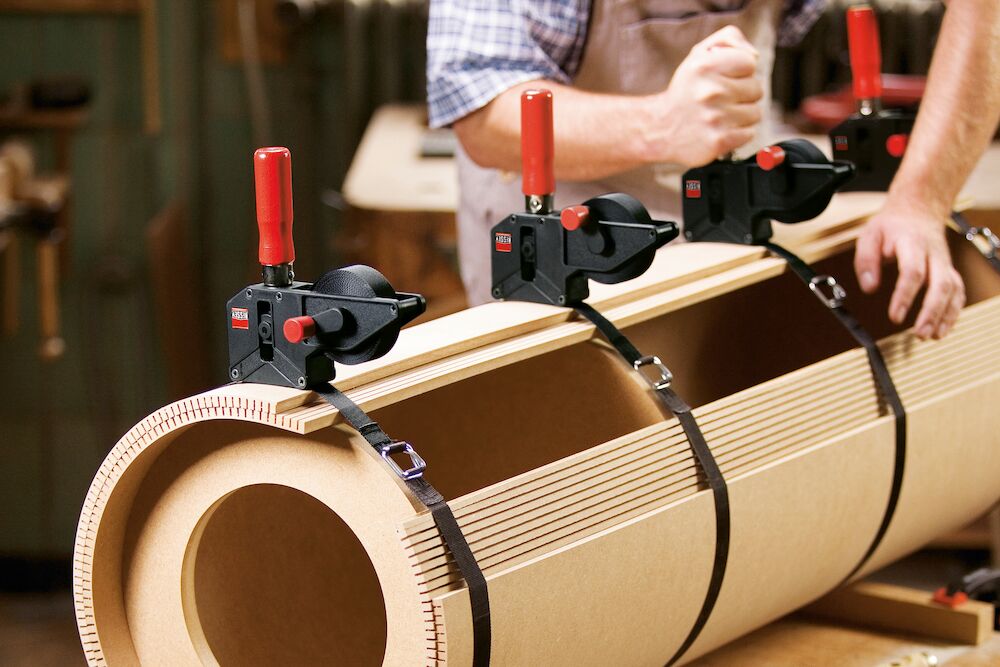

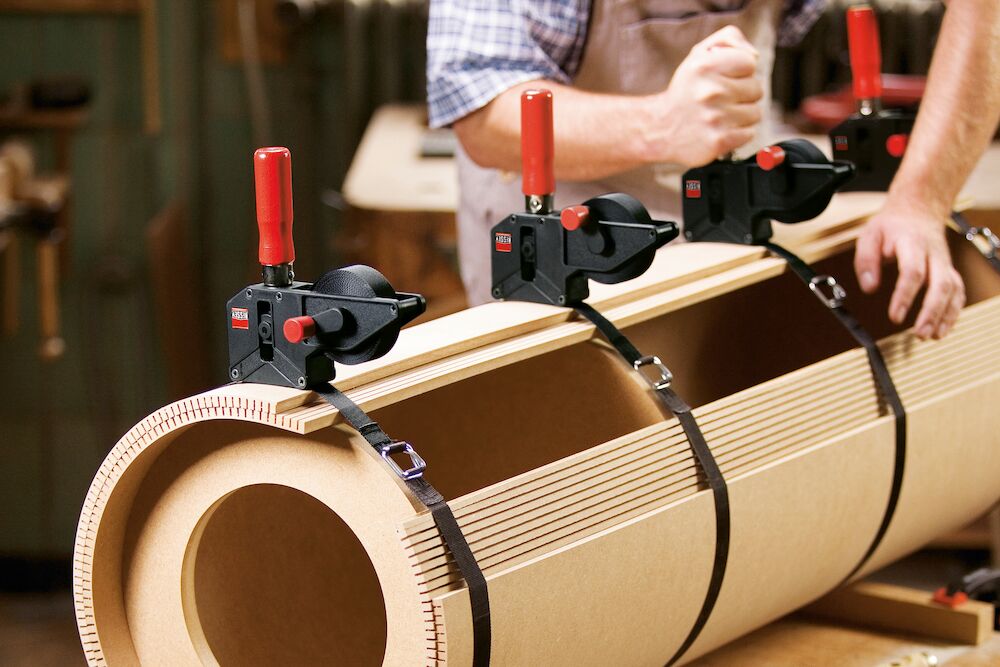

My dilemma

is how best to apply/trim laminations to the front edge,

between each shelf, on the soon-to-be-curved front

edges of the uprights. Gluing will be tedious. I¡¯m thinking

of using dozens of clamps like this:

?

?

But how to

trim the laminations to length after the glue dries? I guess

the flush cut hand saw method is the best one I can think

of.

?

Lucky

?

I'm

not following the need to laminate the front edges

of the uprights? The sides are solid wood,

correct? Are you doing it to cover the slots and

make the front surface proud of the shelves by

2mm? Color me confused...

On Sunday,

July 14, 2024 at 08:25:22 PM MST, David

Luckensmeyer <dhluckens@...> wrote:

Hi

FOG:

?

By

way of update, the aforementioned Leitz

blade is phenomenal. It cuts as smoothly as

any blade I¡¯ve owned which is saying

something for such a large blade with

relatively narrow kerf width of 3.5mm. The

details appear again here, just in case

anyone else wants to consider it as a 400mm

blade option: item number 133130, 400mm

diameter, 3.5mm kerf. 2.5mm body, 30mm bore,

96 teeth, 10 degree irregular pitch, ATB.

?

This

is the first time I¡¯ve used a blade of this

size. The dust it throws off is horrendous;

I assume it has something to do with making

125mm and 135mm deep cuts. My 3M Dustmaster

is in continuous use.

?

?

This

is very fine dust from a couple of hours

work at the saw:

?

In

the end, the powered rip fence and

associated programming has been gold. I¡¯ve

used the special programs on the overhead

display a lot, including rebating,

trenching, etc., but I must say that I have

not really used the specific programming

mode for the Kappa 400. It is wonderful.

?

There

are 10 program positions, and each of those

10 has 100 spaces to enter specific

parameters that can be called up at the

press of an arrow key and the start button

on the overhead display. You can imagine its

use as follows. For the first half lap

joint, I needed a cut at 125mm deep, at

120mm from the end of the Zebrano board. So

for P1 (where ¡°P¡± stands for ¡°Program¡±),

number 1, I¡¯ve entered 125mm blade height, 0

degrees blade tilt, and 120mm rip fence

position. It works out that I need the fence

(which is acting as a bump stop) to move

over 16.1mm to give the half lap width I

need, so I¡¯ve programmed the number 2

position with 125mm blade height, 0 degrees

blade tilt, and 136.1mm rip fence position

for the second cut (i.e. both shoulders of

the lap joint). And so forth and so on for

all 7 half lap joint positions along the

bookcase upright. After 4 cuts, my rip fence

is out at about 1150mm. So at this point I

have to flip the upright end for end and

start again on the final 3 shelf positions

(working from the top of the uprights). This

is made easy using the programming on the

Kappa 400. Obviously my uprights all need to

be dimensioned accurately which I have done.

?

I

forgot to say that I could not use special

programming function which the Kappa 400

offers, where the rip fence can be

programmed for a number of grooves or

trenches of a specific width and depth, at

fixed intervals. The reason? Because my

shelves are deeper at the bottom and much

shallower at the top, so the position of

each half lap joint on the uprights is of

decreasing distance (from the bottom up) and

increasing distance (from the top down).

Programming mode made this process easy.

Seems like cheating. Comparing uprights at

random, and I¡¯d say the 0.1mm claimed

tolerance is verified. I¡¯ve used lots of

compressed air between cuts to make sure

registrations are accurate, and I¡¯d say the

Kappa 400 has worked as advertised. I

strongly recommend a Felder powered rip

fence as a wonderful option.

?

Anyway,

the 3.5mm blade width allowed for 6 passes

to remove the waste for each half-lap joint.

No drilling, no knocking out timber, no

marking lines, and definitely no chiselling.

I¡¯ve decided I can live with the bumpy but

regularly reliable surface in the middle of

each half lap joint.

?

?

Last

night I assembled the first and smallest of

the bookcases. It went together very nicely

but I think I¡¯m going to tweak the Walnut

shelves (through the wide belt sander) so

the fit is less tight. In the picture below,

you¡¯ll see the upper shelves don¡¯t seem the

correct width. That¡¯s because the uprights

have not been curved yet, to reflect the

design where shelves at the bottom are full

depth (260mm) while the shelves become less

deep by the top (210mm).

?

l¡¯ll

use a template to pattern route the curve

after I¡¯m completely satisfied with the

joinery. And then another tricky part is

headed my way: I have to edge laminate 2mm

solid Zebrano onto the front edges of all

the curved uprights. I¡¯ve agonised over this

because I could not cut the curves and

laminate before machining the joints because

I needed parallel edges. Adding the solid

wood lamination to the edge after the

machining is going to be time consuming and

I¡¯m not sure how best to do it. I could

apply over long sections to each curved edge

(between shelves) and then flush them, but

how?

?

-

Router

(risk of splinters)

-

Chisel

(not looking forward to that)

-

Flush

cut hand saw (might be the best option)

-

Cut the

lamination exactly to length and glue it

exactly in position¡

?

If

I used the flush cut handsaw, I could use

overlength Zebrano pieces (but maintaining

continuous grain) and then not stress the

clamping process. I guess after that many

cuts (224 to be precise) I¡¯ll be pretty good

with the flush cut saw? Thanks for your

brainstorming thoughts!

?

?

?

Lucky

?

Hi

David B and Michael:

?

Funny

you should mention the flatbed CNC.

Although not the same, I have been

pondering how much use I¡¯d get out of

a Shaper Origin. That tool would fit

nicely somewhere in my shop!

?

Thanks

David for your vote on the vertical

method. I think the clean corners are

swaying me strongly for that option.

I¡¯ve wondered if I make a very

accurate registration jig and use a

small pattern bit (I can get an 8mm

dia. bit from across town) to

establish the majority of the 20mm

flat across the joint, then there

would be very little chisel work at

all:

?

¡¤????????

corners

squared by the saw blade

¡¤????????

majority

of waste drilled out

¡¤????????

shoulder

established by the pattern bit

¡¤????????

minor

chisel work to finish.

?

Your

jig making has always been a source of

inspiration for me. Your lock mitre

jig is especially egregious! I

absolutely love it. Of course, now I

know I should have made a much larger

vertical jig that does not depend on

the crosscut fence for registration.

Something like what you¡¯ve done would

have been much better. Cheers.

?

Lucky

?

I actually

like your original concept of

using the rip as a bump-stop, a

400mm blade cutting both edges,

and a jig on the crosscut fence to

hold the material vertically.

?Here¡¯s a couple more jig I¡¯ve

made to stimulate your thinking.

?I could quibble over the actual

jig configuration (hence these

photos of jigs I¡¯ve made to hold

vertical materials on the slider

as food for thought).

This is for

cutting lock miter joints:?

?? ??

This one is

for finger joints - which is a

shallower type of thing you are

doing:

?

?

On Jul 9,

2024, at 3:18?PM, David

Luckensmeyer via groups.io

<dhluckens@...> wrote:

?

Oh

wow! The video came

through. I love it. No

one would even think

the drawer is there!

Thanks for sharing.

?

Lucky

?

Lucky, as I

further

thought about

my suggestion

I realized it

was lunacy. I

think you are

correct about

returning to

the horizontal

setup. I know

we are talking

about a lot of

work for 280

repititions!?

I had a few do

overs and

re-designs as

I progressed

but ultimately

was very happy

with the

result.?

To

answer?your

question, it

is a drawer

that holds

DVD¡¯s on the

bottom level,

and Blu-rays

on the top

level as they

are both

different size

cases. The

drawer was

incorporated

into a raised

panel

staircase I

built 30 years

earlier and

had always

planned to

make a drawer

similar.

There is

hopefully an

attached video

below showing

final

install??

The CMT was

excellent;

best dado I

ever had but I

ran it on a

cabinet saw,

not on my

K700S. I used

a simple ¡°box

joint jig¡±

that we all

learned in

woodworking

101 but made a

mistake

thinking I

could do the

sides

separately and

still have

things line

up. A couple

of tries

changing

methodology

were

necessary. The

drawer empty

without the

drawer front

was over 75

lbs made of

Maple. I used

Blum slides

(Blumotion)

with ?¡°Tip-on¡±

added for push

to open tech

to eliminate

visible

exterior

hardware.

?

On Tue, Jul

9, 2024 at

5:41?PM David

Luckensmeyer

via

<dhluckens=[email protected]> wrote:

Imran:

?

Thanks

for your

ideas. You¡¯re

correct about

the slotting

blade. If I go

the vertical

machining

route I¡¯ll

need nearly

every bit of

the 400mm

blade¡¯s depth

of cut. If I

were to go

back to the

horizontal

setup, I could

remount the

dado blade,

set it to

maximum

height, and

make a partial

cut. This may

well be a

better

solution

because it

gives me the

exact width

(to match the

existing

shallower

trenches).

?

You

have rightly

identified the

time-wasting

point of

needing to

take two

passes

(minimum) and

then deal with

the waste by

drilling a

hole with a

forstner bit

to get rid of

the septum. I

would then

have to mark

and chisel the

waste which is

fine for 1-10

joints, but

not 280

trenches¡

?

Brian:

?

That

looks awesome

what you¡¯ve

made. Is it a

drawer insert

for plates?

I¡¯m very

curious what

you thought of

the new CMT

dado stack?

What did you

like? What

didn¡¯t you

like? Thanks

for sharing.

I¡¯d rather not

run two 400mm

blades on the

slider. So

much to go

wrong! EEK.

?

Joe:

?

Love

those jigs.

Pictures speak

volumes. So

many ideas to

learn from.

Thank you.

?

Methodology

Quiz

How

would you make

280

non-through

cuts that have

to be

precisely

machined at

125mm deep and

20mm wide?

?

-

Vertical

method as

discussed to

date using the

400mm

sawblade, to

make two cuts

to establish

each shoulder,

drilling out

the waste, and

then A) mark a

line and use a

chisel to

square up the

joint, or B)

use a router

and small

pattern bit to

establish the

shoulder and

then chisel

out the

corners.

?

-

Horizontal

method using

the same dado

stack that

machined the

shallow

trenches, dado

raised all the

way up for the

stopped cut,

and then

employ either

option A or B

above to clean

up the joint.

?

-

Rely on

the existing

shoulders of

the trenches

(5mm deep on

both sides),

and use a

router and

pattern bit to

obtain the

125mm ¡°half

lap¡± joint,

and then

square up the

joint using

option A or B

above.

?

-

Something

else?

?

I

personally

can¡¯t see a

way to avoid

handwork of

some kind. The

reason why I

favour the

vertical

method (as I¡¯m

calling it) is

because I can

get precise

and square

internal

corners for

the stopped

cuts. I find

it much easier

to clean out

the waste if

the corners

are already

established. I

have never

liked

chiselling

corners

square, even

with a square

chisel (e.g.

Veritas). And

I would

hate

chiselling 560

corners!

?

Thanks

in advance for

your input,

Lucky

?

I

have another

more stable

jig for

demonstrating

tenoning on

the slider

that could be

adapted for

this also.

?

--

Michael Garrison Stuber

|