Keyboard Shortcuts

Likes

Search

Radial Drill Press purchase

|

I became interested in a better drill press back in 2013. ?I received information here about the RF-45 and many possible modifications. I came close to buying it, but something just did not seem right for a few reasons, and I ended up with a new Powermatic. ?I have not really been too happy with it. ?There were a couple of comments about vintage radial drill presses, but I did not want one of those beat up units in poor condition that needed TLC big time as I am not skilled in total restoration. ?This one was the best one I have seen

This past week I found a Rockwell Radial drill press that seemed to be in great shape, similar to the above. ?I just purchased it today I am not sure if it is 110v or 220 etc but I can work with either and single or 3 phase. ?When I get it, I will consider what would be the best motor setup, but it seems like the ideal would be forward and reverse and the ability to change speeds over a wide range without changing belts. ?I suppose there are modifications that can be made. ?I saw someone changed the column raising to power feed. Not sure how that works. If I understand, the width is around 34 inches or so and the depth is 48 inches. ?That will allow it to fit where my Powermatic is. ?To the left is a butcher block work bench, and I am thinking I can set the drill press table flush with that to increase my work surface area. ?I will make an accessory table and fence with stops, and slots to accommodate the Automaxx clamps ?I like the idea of a fixed height table. Anyhow, I think for me this is better than the drill mills for a woodworking application. ? |

|

Cliff Rohrabacher, Esq.

开云体育I have one? it's a great machine. you will really like it. I pulled the? 3 phase half horse motor off and replaced it with a

220? Reversible? full horse.? I put on a drum switch by passing

the stock one. Then I wanted to move it ?so I got some heavy casters and?

mounted them and cut the legs to accommodate. The? height adjustment is a bit of a PITA so I cheated. I built a plywood box that goes on the table to give me different heights.? the? drill is no good for drilling steel.? It is no where near

rigid enough. For that I have a full size vertical knee mill. ONE SAFETY ISSUE I DISCOVERED. my former drill was an old

walker turner.? The table is way smaller.?? The column in the back

would stop most things from spinning out of control if they got

away from me.?? NOT SO WITH THE RADIAL DRILL.? that sucker will

grab? the work? spin it like who dun it and whack you? brutally

hard in the torso or worse? take it on a ripping tear through your

flesh. .? Not a good moment.? DAMHIKT? Never take a water bottle

to a sword fight. I wondered how I missed that.? The answer was I'd never run a

radial drill before so I lacked the ingrained? safe habits? that I

have for most every other machine.

On 2/12/20 1:24 PM, joelgelman via

Groups.Io wrote:

I became interested in a better drill press back in 2013. ?I received information here about the RF-45 and many possible modifications. I came close to buying it, but something just did not seem right for a few reasons, and I ended up with a new Powermatic. ?I have not really been too happy with it. ?There were a couple of comments about vintage radial drill presses, but I did not want one of those beat up units in poor condition that needed TLC big time as I am not skilled in total restoration. ?This one was the best one I have seen |

|

Those are great if you do a lot of odd compound angles and want deep reach. As Cliff notes, it's not very rigid with respect to what steel drilling requires, but plenty rigid for wood and small diameter metal.? Also the spindle diameter is pretty small and it's common that the spindles have significant runout (the head/spindle assembly is common to a zillion Walker Turner/Rockwell models)? ?

There were quite a lot of those made.? A decade or so ago there'd be multiple of those on eBay at any given time, but they seemed to have become pretty scarce in recent years.? However, some of this traffic seems to have moved back to craiglist too.? Back in the heyday I saw dozens in shops and auctions, and they were rarely super beat up.? It seems like a lot of metal shops had them, but didn't use them much because for straight drilling other drill presses were better (more rigid, more powerful) That one seems in fine shape, but I would note that a recent re-paint is a red flag.? You can see the over-spray on the floor.? And of course these didn't come in white -- machine gray only.? ?There are some sellers who just spray everything to make it shiny, but often recently painted means it looked too crappy to sell at top dollar.? But there's very little in a simple old pulley-driven drill presses anyway.? If the bearings are crappy, it's easy to replace.? The main issue is if the spindle is bent slightly and runout is lousy. |

开云体育Nice Drill press. It’s 220V single phase according to the listing. I would swap out a 220V three phase motor of 1 to 2hp and put a VFD on it. then put the front belt in the middle position and you should be able to use the VFD for slow to fast.

|

开云体育Joel,?Sorry to say this? Your link is what is called a ram drill press. They are mores taper and not a mill in any way. Just a glorified drill press with way to many things going on to be reliable. They also put a saw on ram as a radial arm saw agin to much happening to be reliable. Here is a pick off the net of my Japanese azuma ?also not a mill just A drill press. For tapping reaming and drilling larger stuff. martin/campshure/co/llc mac campshure 608-824-0023?fax Designing and building for 47 years On Feb 12, 2020, at 12:25 PM, joelgelman via Groups.Io <joelgelman@...> wrote:

|

开云体育I had one ?in 70’s with a gear drive saw on it and in 90 ‘s had one with drill head ?and hated both of them.Mac,,, martin/campshure/co/llc 608-824-0023?fax Designing and building for 47 years On Feb 12, 2020, at 2:45 PM, Mark Foster <mfsta2lt@...> wrote:

|

开云体育Perhaps Mark is using his for wood, while you using them on metal? On a semi-related note, I absolutely adore my 1950's DeWalt GA

Radial Saw.? Tuned properly, treated well, and equipped with the

right blade, a well-built radial saw can provide consistent,

repeatable, and accurate results.? That said, there are a lot of

crappy radial saws out there should be melted down. -- Michael Garrison Stuber On 2/12/2020 12:51 PM, mac campshure

via Groups.Io wrote:

I had one ?in 70’s with a gear drive saw on it and in 90 ‘s had one with drill head ?and hated both of them. -- Michael Garrison Stuber |

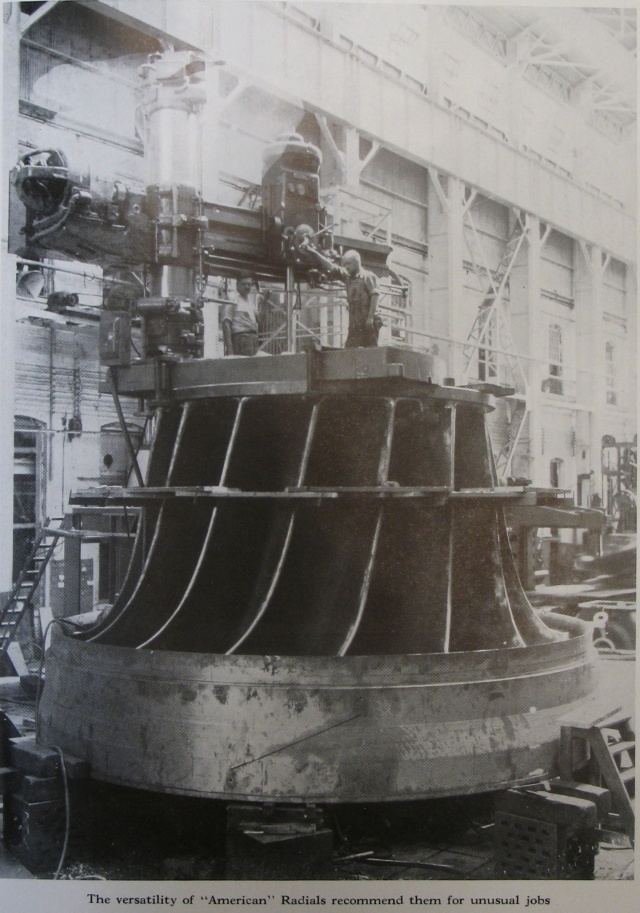

开云体育Micheal,? I am a craftsman and work in all media. Couple famous radial picture of web. I like the picture of the large radial with the small probably 18” post and 6’ arm ?mine is 1/2 the size 10” x 3’. The big one is probably 30” post and 15’ travel . You see the big ones when you get around ship yards. Mac,,, martin/campshure/co/llc 608-824-0023?fax Designing and building for 47 years On Feb 12, 2020, at 2:55 PM, Michael Garrison Stuber <mtgstuber@...> wrote:

|

|

WTF, sorry,

Did not know that even exist, I would have said photoshopped picture, but I found the following pictures on practical machinist and there are tons of them other there. I also remember the motto: bring the tool to the workpiece and not the way around. I see now that this motto apply to more than a Festool domino :)    Bill |

|

I grew up in Cincinnati and was friends with some of the leBlond clan, Cincinnati incorporated (Cincinnati shaper) and Milacron - I have seen some really large machine tools, Cincinnati is flooded with them, at least they were

toggle quoted message

Show quoted text

Regards, Mark On Feb 12, 2020, at 4:35 PM, Bill James via Groups.Io <xxrb2010@...> wrote: |

|

My application is to drill holes in wood and only wood. ?On the recent re-paint red flag comment, I noted that the youtube video was from 2017 and so it seems the the machine was painted in 2017 or prior to that, but the machine was just recently for sale.

A little video of the similar machine at 4:38 |

开云体育Joel ,?If your using for wood than will be jolly ok they fall apart with metal, also with so many moving parts and angles and the such it is hard to keep everything in position. For the word stuff they can solve the problem. martin/campshure/co/llc 608-824-0023?fax Designing and building for 47 years On Feb 12, 2020, at 4:39 PM, joelgelman via Groups.Io <joelgelman@...> wrote:

|

|

I have an 1100 series floor standing Walker Turner with auto down feed made in 1951. I have been using it for almost 40 years on both wood and metal. After all that time the top bearing went out. I found Walker Turner Serviced Machines in CT has the special bearing reproduced so I am in the process of restoring it (stripped and repaint) and expect my kids to get another 70 years of service out of it.

|

|

Hey Joel

My drill press is a delight to use.?? Check it out:? What amazes me is forstner bits and drill bits that I considered less than ideal when drilling with my previous drill press now create very clean holes with very little effort. The larger than usual table is about 16" (>400mm) square. Cheers David |

|

David, thanks for the feedback. I am familiar with that unit. ?What I like most about a radial drill press is the fact that the table does not move. ?I want to be able to set the height of the table flush with surrounding work surfaces and to better setup my fence and stops. ?I like the idea of being able to have more distance from the column as a bonus. ? I believe that the vintage machines are better made than the new ones.?

I hope I like it better than the conventional drill press. ?I will find out! |

|

I stumbled across Mike's site when watching some Sam Blasco videos. ? Dave Davies? On Fri, Feb 14, 2020 at 8:16 PM joelgelman via Groups.Io <joelgelman=[email protected]> wrote: David, thanks for the feedback. I am familiar with that unit.? What I like most about a radial drill press is the fact that the table does not move.? I want to be able to set the height of the table flush with surrounding work surfaces and to better setup my fence and stops.? I like the idea of being able to have more distance from the column as a bonus. ? I believe that the vintage machines are better made than the new ones.? --

Dave & Marie Davies 318-219-7868 |

开云体育Hi Joel,?Make darn sure the seller tightens all handles and be sure to check before you unload ?if and handle is not locked they are a very unstable load and could end up on the ground. Mac,,, martin/campshure/co/llc 608-824-0023?fax Designing and building for 47 years On Feb 14, 2020, at 8:16 PM, joelgelman via Groups.Io <joelgelman@...> wrote:

|

开云体育Thanks for the info David D,Did not know Michael was still around, he is very particular and been making his fences for a long time. I wouldn’t hesitate to buy his products. time true and tested. Mac,,, martin/campshure/co/llc 608-824-0023?fax Designing and building for 47 years On Feb 14, 2020, at 8:19 PM, David Davies <myfinishingtouch@...> wrote:

|