Keyboard Shortcuts

ctrl + shift + ? :

Show all keyboard shortcuts

ctrl + g :

Navigate to a group

ctrl + shift + f :

Find

ctrl + / :

Quick actions

esc to dismiss

Likes

- MicBuilders

- Messages

Search

|

Re: Sourcing felt pads for mic capsules

Hello, You could also try with ethanol (ethyl alcohol), a high proof one (generally 96%) used to treat and desinfect wounds.? A ter?a, 11/06/2024, 23:31, Slobodan Ljubisic via <ljubisic=[email protected]> escreveu:

|

|

Re: What is with this trace? (Lavalier Teardown: Shure WL185 with RF CommShield)

Le 12/06/2024 ¨¤ 11:01, sergio_logic via groups.io a ¨¦crit?:

DPA seem to be looking down at external contributions. I wrote them about a misconception in their "condenser vs. dynamic mics" Mic University discussion. They answered, even the junior engineer that had written the article, but they never correct the article. |

|

Re: Sourcing felt pads for mic capsules

Thank you very much for sharing this information with us. Yes, this is what I was looking for. ?Looks a bit expensive for what it is - but since it cannot be found anywhere else, it is what it is. :)

On Wednesday, June 12, 2024 at 02:01:16 AM GMT+2, Zander <zanhulme@...> wrote:

Micbooster stocks at 10mm and also a 5.8mm: Take note that that's the single price though ¡ª I accidentally ordered only 1 when I meant to order a sheet, and I live on the other side of the planet so I wasted a lot of time and postage! |

|

Re: [allowed] Re: [MicBuilders] True tree ears or DYI binaural dummy head.

¿ªÔÆÌåÓýYes, the silica in bamboo blunts power tools terribly. I had great issues in a straw and miscanthus processing plant, where hardened steel blades were needed on the straw shredding tools; but for bamboo, I believe carbide-edged tools are commonly used. |

|

Re: What is with this trace? (Lavalier Teardown: Shure WL185 with RF CommShield)

Hi Scott,

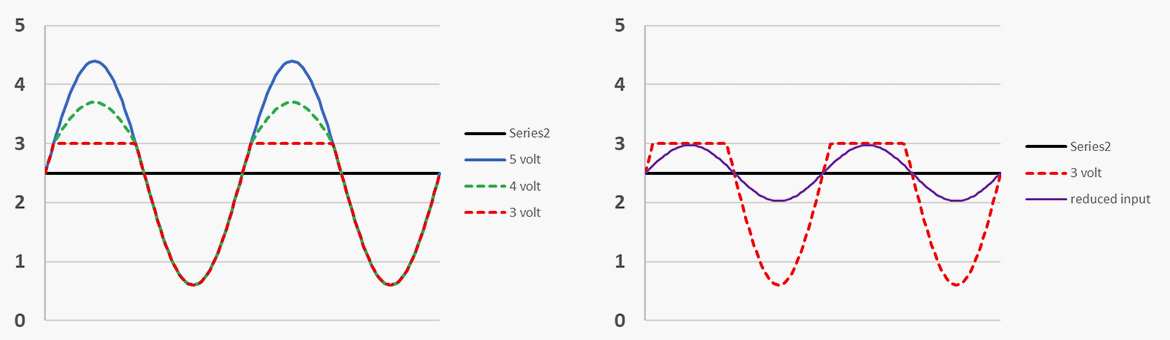

I'm a pretty serious pinout nerd in that world, if you need info please feel free ask.I'm going to take you up on that offer. I don't know if you are familiar with Sony UWP bodypack wiring (it's probably less popular than Shure/Sennheiser in the US, whereas in Europe it has a pretty fair share with Sennheiser in the TV studio market) Sony UWP uses 1/8" (3.5mm) TRS jack with the following wiring: Tip - audio and 7k/9k Ohm bias resistor to ground (varies a bit among generations, UTX-B03/B40 are 7K, old UTX-B2 is 9K) Ring - 5V (through ~330 Ohm current limit resistor) Sleeve - GND Now, knowing this pinout, how would you go about connecting a DPA 2-wire lavalier to Sony UWP?? DPA this: "DPA miniature and subminiatures should never be connected to a compensational circuitry as it may reduce the already optimized output. In the adapter connection scheme of DAD6010 (MicroDot to 4-pin connector) which is shown below, pin 4 (for active load) is not connected." -- so in the case of the Shure pinout you mentioned, they make a point about NOT connecting the load resistor. Yet, their $105 adapter DAD6019, listed as with Sony UWP, does exactly that, it's just a 3k3 ohm resistor from 5V to Tip (audio and 7K to ground). This means, that even under no load, the voltage at the microdot is ~3.3V = 5V*7K/(7K+3K3+0K33), as measured .  What happens if the voltage is below 5V for these mics spec'd for at least 5V? DPA answers : "As mentioned, the output signal depends on the supplied DC voltage. If it is too low, it may result in asymmetrical clipping of the audio signal above a certain level [see figure 4]", and "If the available bias voltage is, say, 4 or even 3 volts, the microphone still works. But the acoustical input must be reduced and kept below a limit, lower than the usually specified max SPL; this is to avoid distortion."  This is precisely what happens with the DPA DAD6019 adapter, although DPA mentions no max SPL limitations introduced by the adapter: I've made my own adapter which biases the mic through a 3K3 (metal film) resistor between the 5V and the mic wire (as all the adapters for the 5V systems do), but then only AC couples it to the Tip (SMD tantalum, anode at mic), effectively removing the Sony's 7K resistor from the DC bias. The build quality is not like the DPA, but it's not $105 either. Of course, this fixes the positive swing issue: (Note, my "sound source", an iPhone loudspeaker, was distorting the sine, not the mic.) I wrote all this to DPA ~1 year ago, they replied but only said they will investigate. They have not updated the schematic of the DAD6019 in the meantime. So, do you think there is another way around this? My "A-frame" made of a cap and resistor is not the most mechanically sound solution, but it seems electrically correct. |

|

Re: Sourcing felt pads for mic capsules

I've bought a set of punch "things" (don't know the english name). I can punch the covers out of different materials in different?sizes. You find different kinds of felts and fabrics in handcraft stores. Picture of the punches: Am Mi., 12. Juni 2024 um 02:01?Uhr schrieb Zander via <zanhulme=[email protected]>: Micbooster stocks at 10mm and also a 5.8mm: |

|

Re: AOMs-5024 in enclosures from China

I got your point. Yet such things puzzle me, because if there is no difference at all then why produce them in two versions? Most small electrets got felt covered face by default. For some reason they offer same capsule version without felt. There must be some purpose and intention.

|

|

Re: Sourcing felt pads for mic capsules

Believe or not I've done that already, but results are sometimes great and sometimes not. Like some glue is left on the "donor" capsule and pad doesn't stick as it should.

On Tuesday, June 11, 2024 at 10:13:08 PM GMT+2, pmfalcman <pmfalcman@...> wrote:

I saw them once on Ali but now, of course, I cannot find them. Just buy cheapest capsules with these pads, heat them with a hair dryrier - this would soften the glue, remove and then stick on your mics |

|

Sourcing felt pads for mic capsules

I am having trouble getting these self-adhesive felt pads for microphone capsules (10mm ones, like Primo EM272 etc). I have tried Amazon, Aliexpress etc. - but cannot find anything like this.? The purpose of the pad would be to protect the capsule from dust etc getting in, as much as possible. It would be very handy if there were some self-adhesive pads of this diameter that I could just stick on the capsule. But all I could find in this diameter were the ones for use on unglazed pot bases to protect furniture and worktops - these are too thick (to be used to cover holes in the microphone capsule), I am afraid? The felt pads for furniture (chairs for example) are even thicker.? Any advice on where to get them or what to use instead? |

|

Re: Updated Hydrophones

toggle quoted message

Show quoted text

On Jun 11, 2024, at 13:30, Adrian Hicks via groups.io <mail@...> wrote:

|

|

Re: Updated Hydrophones

Or even easier, give the the diameter and length, as in the length of the straight portion. From there I'll just add the hemisphere to the base and life will be good. Saves CAD faffing On Tue, Jun 11, 2024, 19:27 Adrian Hicks <mail@...> wrote:

|

|

Re: Updated Hydrophones

Should be able to punt a STP from that or just screengrab the sketch profile of the revolve that is the actual form as moulded. Even if it isn't metric ? On Tue, Jun 11, 2024, 19:25 Jules Ryckebusch <ryckebusch@...> wrote:

|

|

Re: Updated Hydrophones

¿ªÔÆÌåÓýI did it in Fusion 360 if that helps with any format I can export for you.Best Regards, Jules Ryckebusch? On Jun 11, 2024, at 13:03, Adrian Hicks via groups.io <mail@...> wrote:

|

|

Re: Updated Hydrophones

I'll happily take the STL from the instructable and convert the form into a split mould. I do CAD all day and have history of making tooling for Carbon Fibre parts, so it's a pretty easy process. If you could export as STP it would make life much easier as the CAD system I use doesn't play nicely with STP. On Tue, Jun 11, 2024, 19:00 Jules Ryckebusch <ryckebusch@...> wrote:

|

|

Re: Updated Hydrophones

¿ªÔÆÌåÓýlol I do have a 3D printer. Just not enough time in the day lol ?Best Regards, Jules Ryckebusch? On Jun 11, 2024, at 11:21, pmfalcman via groups.io <pmfalcman@...> wrote:

|

|

Re: Updated Hydrophones

Jules - in the instructable you wrote that you want a silicone mold.

First - you can make it yourself. I gather you have a 3D printer so you can print a form, get a molding silicone from a jewelry supplies shop and make one. Though I suspect that demolding long hydrophone body may be problematic. Soooo.... Why don't you print a reusable split mold? Two parts split vertically, with wings to clamp or (better) screw together. Thick walls, obviously. Mold release wax should seal the junction enough so the resin wouldn't leak. |

to navigate to use esc to dismiss