Keyboard Shortcuts

Likes

Search

Pulleys and Belts instead of gears

|

I was always disappointed by the jerkiness of the Athearn rubber band drives.? Possibly some modern O-rings may do better. I would look at toothed belts if it were not for the right angle problem.? Getting rid of the noise with new properly fitted worm and gear might be a satisfactory solution as well.? Chuck Peck On Mon, Feb 19, 2018 at 9:26 PM, rh@... [yardbirdtrains] <yardbirdtrains@...> wrote:

|

||||||||||||||||||||||||||||||||||||||||

|

Spring belt might be better than rubber bands. The issue will be the belt climbing in a 90 degree drive. Springs work somewhat better due to round cross section. But: You have zero gear reduction. Think Athearn Hustler, with wheels much smaller and a motor shaft..less than 1/8" and a BIG axle... and they still set land speed records. You will need to get the driver off, gear off, find an old Athearn axle, drill and fit and attach the Athearn drum.....and hope the armature is long enough to keep the belt from falling off the end. Me? -----Original Message----- |

||||||||||||||||||||||||||||||||||||||||

|

I would think spring belts would suffer the same defects as the rubber band drives.? Stored energy on acceleration and uncontrolled release on deceleration.? Chuck Peck? On Mon, Feb 19, 2018 at 9:41 PM, Dave woebegone@... [yardbirdtrains] <yardbirdtrains@...> wrote:

|

||||||||||||||||||||||||||||||||||||||||

|

Thanks for all your replies. They are exactly what I was hoping for. This is an experimental project so an and all inputs are very welcome. My feeling is that if I can find the right pulleys and belt (not too loose and not too tight) this'll work very well. I already have a long shafted Sagami motor that should provide the correct amount of power. Now I am searching for the pulleys. The motor has a 1.5mm diameter shaft. Any recommendations?

Richard in Vermont |

||||||||||||||||||||||||||||||||||||||||

|

Thanks for all your replies, that is exactly what I was hoping for. This is an experimental project so any and all inputs are very welcome. I have to make a correction before going any further. The locomotive I¡¯m working on is not a Mantua 0-4-0 but rather a John English 0-4-0 which is quite similar in construction. I have several Mantua 0-4-0¡¯s that I have been working on, mainly to try to eliminate the noisy gear problem. Someone mentioned a NWSL gear box and I have successfully done that previously but it usually requires milling out some of the boiler metal and I lack the machining ability to do that not to mention the extra expense involved, but those little gear boxes are an excellent way to eliminate gear growling.?

My problem now is to find the correct pulleys and belt combination. I already have a Salami can motor with a long 1.5mm diameter shaft. I have ordered an assortment of plastic pulleys from China that may give me what I want but unfortunately they don¡¯t give much info as to what is in the assortment so this is a gamble. Some nice precision brass pulleys would be nice to find. Any suggestions? Richard in Vermont |

||||||||||||||||||||||||||||||||||||||||

|

This is, once again, something I've thought about but not actually experimented with for lack of a layout so bear that in mind... I have a few Varney spring drive F3s and I did find some O rings at a plumbing supply store that fit and were quiet. Can't say how durable they'd be. I love that you can change the gear ratio on those Varneys by simply moving the belt to another slot and there's no question they are quieter than the later gear driven locos. So I also have a couple of Varney NW2s and I found myself wishing they also had a pulley system. The solution I thought about (but haven't tried yet) would be as follows: Two ways to make your own pulleys: 1.) Take existing wheel sets and pull them off their axles and push them onto a drive shaft with the flanges facing towards each other and glue them together. You could make varying ratio pulleys out of 33",36", 40", etc., wheel sizes.

toggle quoted message

Show quoted text

2.) You could press together any size drivers and axle gears.. even 80" steam drivers if you'd like.. to make a toothed pulley. The larger diameter of the drive wheel on each side of the axle gear holds the belt in place. 70s Tyco diesels have the axle gear molded with the plastic drive wheel as one piece. Press two of those together.? Jeff jppellas@... -----Original Message-----

From: rh@... [yardbirdtrains] To: yardbirdtrains Sent: Tue, Feb 20, 2018 01:47 AM Subject: [yardbirdtrains] Re: Pulleys and Belts instead of gears

?

Thanks for all your replies, that is exactly what I was hoping for. This is an experimental project so any and all inputs are very welcome. I have to make a correction before going any further. The locomotive I¡¯m working on is not a Mantua 0-4-0 but rather a John English 0-4-0 which is quite similar in construction. I have several Mantua 0-4-0¡¯s that I have been working on, mainly to try to eliminate the noisy gear problem. Someone mentioned a NWSL gear box and I have successfully done that previously but it usually requires milling out some of the boiler metal and I lack the machining ability to do that not to mention the extra expense involved, but those little gear boxes are an excellent way to eliminate gear growling.? My problem now is to find the correct pulleys and belt combination. I already have a Salami can motor with a long 1.5mm diameter shaft. I have ordered an assortment of plastic pulleys from China that may give me what I want but unfortunately they don¡¯t give much info as to what is in the assortment so this is a gamble. Some nice precision brass pulleys would be nice to find. Any suggestions? Richard in Vermont

|

||||||||||||||||||||||||||||||||||||||||

|

Pulleys work in parallel lines...straight through. They aren't happy with 90 degree turns. Square cut bands and four sharp corners that will try to ride up. You can't use a pulley on the motor shaft. Because....it is too large a diameter, even the smallest you can find. Then you're going to have to move the nose on the motor up high enough to get the band/belt to have some room for the 90 degree turn. With the nose up you will still have to mill out the underside of the boiler. I remember one specific Lionel H0 diseasemal, where there was a belt and pulley on each end, parallel (sort of) to allow truck rotation...lower pulley on worm shaft in truck. Couldn't keep belts on the pulley. Sitting in a junk box now. -----Original Message----- |

||||||||||||||||||||||||||||||||||||||||

|

Richard,

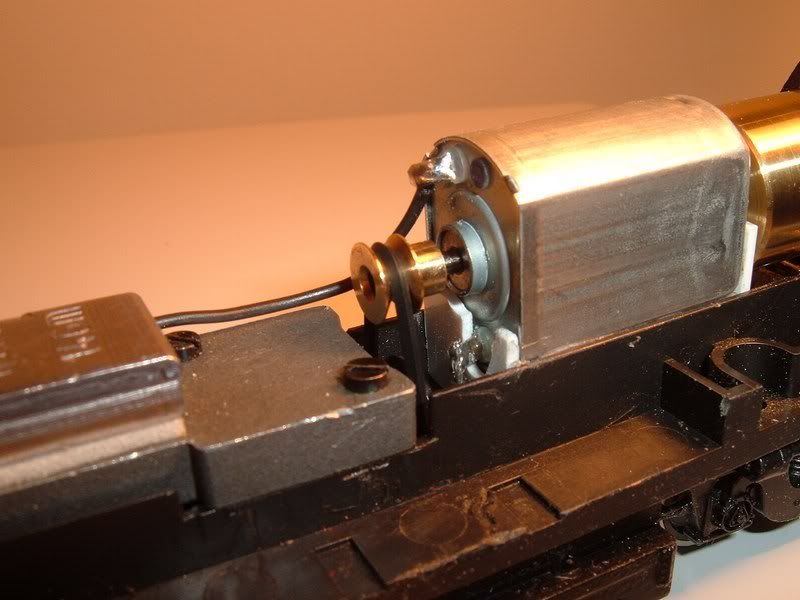

You can find pulleys in old tape drives, and even some computer disk drives use a belt and pulleys for the drawer mechanism. I did a repower on a Riv U25C years ago with a small square belt and pulleys that worked really well. http://i159.photobucket.com/albums/t131/NickelPlate759/Rivarossi%20U25C%20Belt%20Drive/DSCF0368-800x600.jpg

? http://i159.photobucket.com/albums/t131/NickelPlate759/Rivarossi%20U25C%20Belt%20Drive/DSCF0390-800x600.jpg

? The small pulley on the motor shaft and large one on the gearbox add some extra reduction to the gearbox, but with a steamer all of your reduction would be limited to the pulleys alone. That's probably going to make it too fast, even if you make the pulley on the axle as close to the driver diameter as possible. I would cut a groove for the belt into the existing axle gear if I was to try it, though. Nelson |

||||||||||||||||||||||||||||||||||||||||